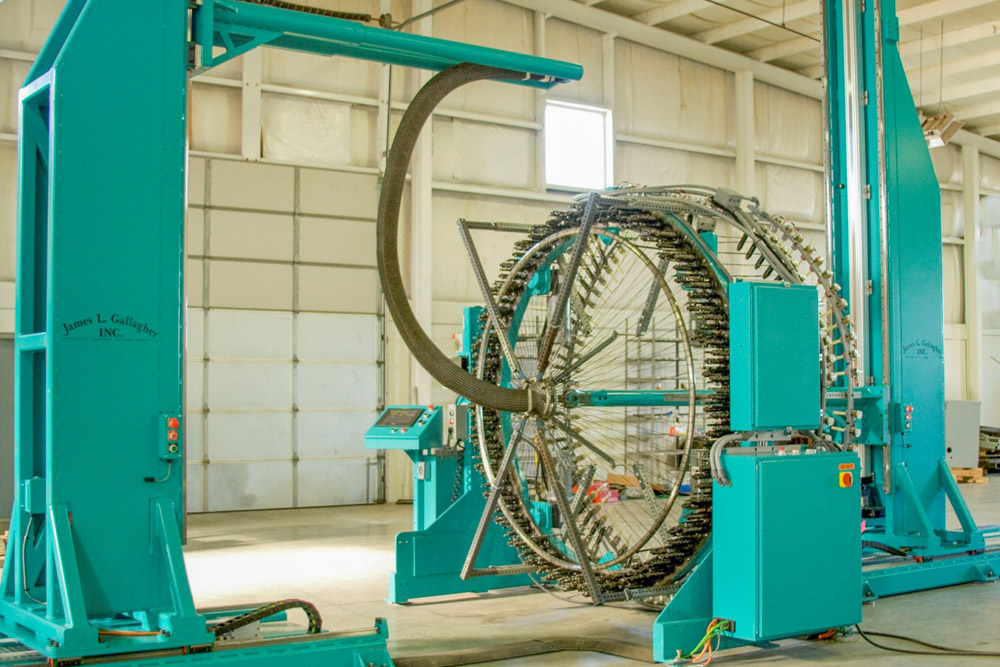

100,000-Pound Pultrusion Machine

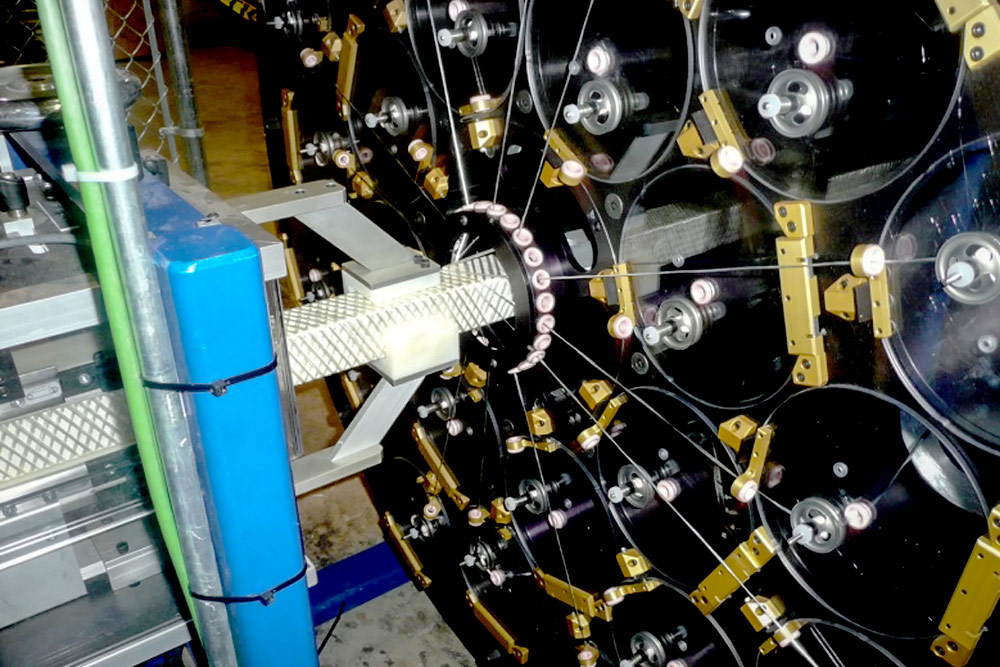

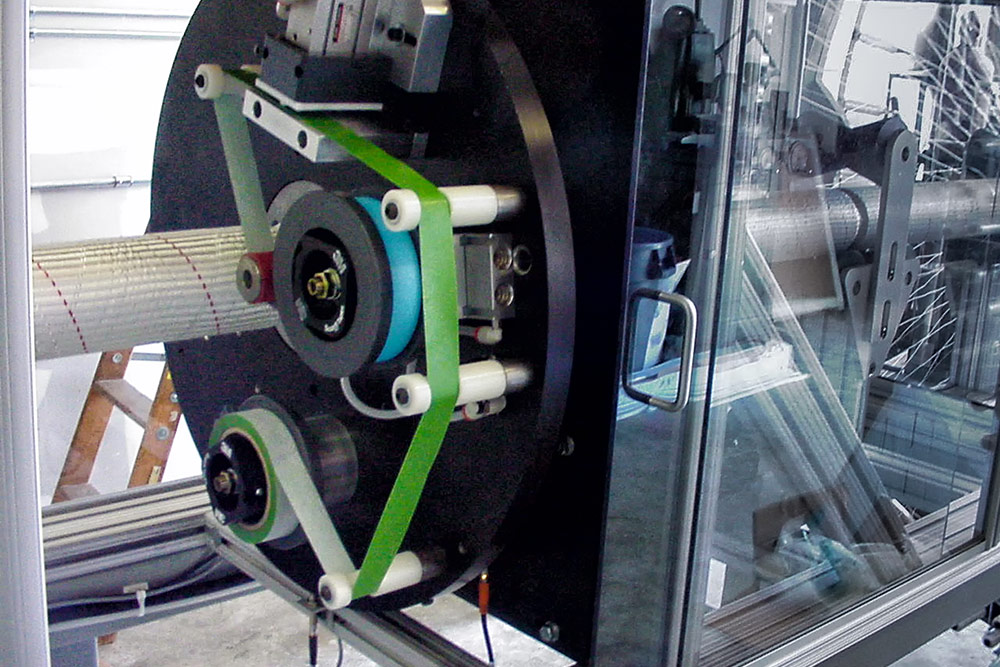

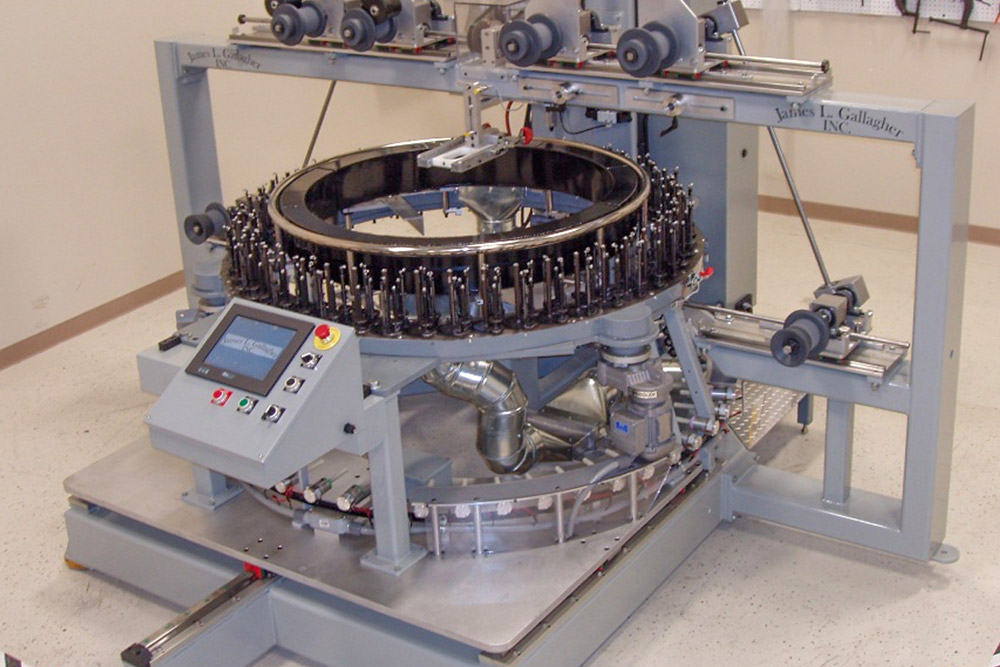

Gallagher was part of a team asked to develop a new pultrusion process to produce high-performance composite canisters used in an air defense system. The project was funded by a federal Small Business Innovation Research (SBIR) Phase 2 grant.

The canisters deployed in the existing defense system were made by filament winding. A Phase 1 proof of concept study showed that pultruding the canisters could reduce the cost of manufacturing by as much as 25 %, while retaining performance standards of the finished product.